Knife Making Courses

Discover the fundamentals of traditional knife making in Our Suffolk Forge

This is a one-day knife-making course designed for both beginners and those who have prior experience blacksmithing. Our expert team will guide and support you through each process in the design and forging of your own unique knife, that you will cherish forever, along with a special story to be told.

Our Day Courses

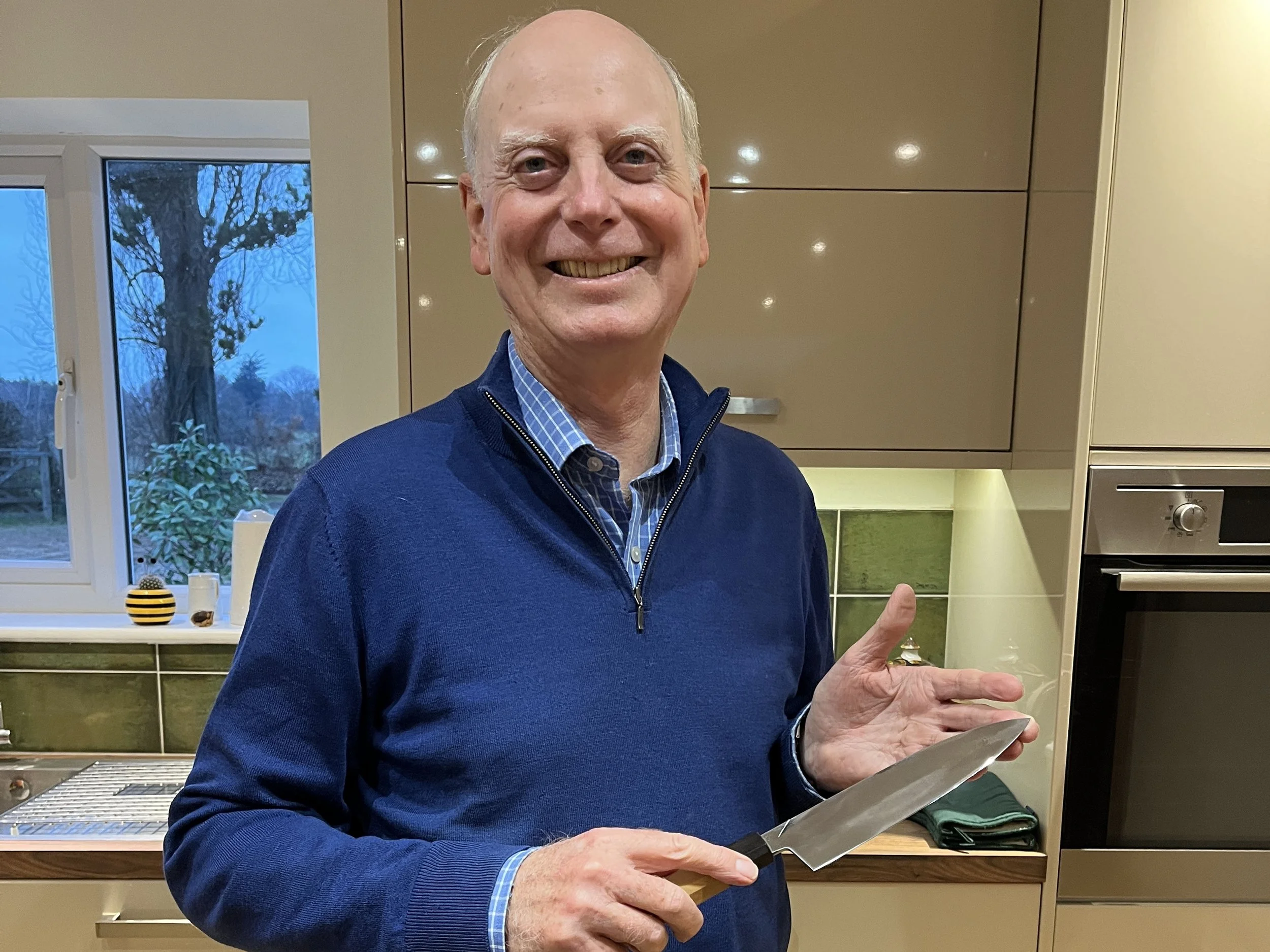

Our day courses are specifically designed to take anyone from the complete novice through to the experienced wood or metal worker, and through close training and help, coach them through the process of making a kitchen knife, camp knife or chopping board. Not only does this give a massive boost to their self esteem and confidence, but sends them home with a beautiful heir loom their family will cherish for generations to come.

-

Absolutely no experience required. Toby has taught everyone from children to great grandparents and retired accountants to trainee nurses.

-

We welcome groups of friends to come and take part together – simply book the number of people when making your booking.

-

Our instructor has years of experience, so rest assured you’re in great hands.

1 - WHEN YOU ARRIVE

You’ll be greeted by your instructor for the day with a coffee or tea, there will be a quick but thorough safety briefing. The forge is an exciting place, but you’ll need to be aware of a few things you might not want to put your fingers in. This is the time to say hello, ask any questions and don your safety gear.

What you will do

2 - FIRING UP THE FORGE

High carbon steel is very hard in its normal state and very difficult to manipulate, but when it’s heated to around 1000c in one of our gas forges, it enters a plastic state meaning it can be hammered into a desired shape. Forging when it pertains to steel has been performed for well over 6,000 years, to 4000 BC and even earlier. While it takes a level of physical fitness, I have students as young as 6 and as old 90.

You will take a piece of steel and forge in the tang, which is the part that attaches the handle to the blade. Then flip the steel around and forge a distal taper, bevels and point onto the blade.

3 - QUENCHING THE BLADE

The knife blank you have made while hard to the touch is soft in knife terms. This means it would not hold an edge and would not be fit for use as a knife. Heating the steel to it’s critical temperature, and quenching (cooling rapidly) in special oil, causes the steel to become very hard.

4 - GRINDING THE BLADE

Now your blade is nice and hard, but it’s still too fat to cut anything, let alone carrots or potatoes. The blade is profiled and shaped on one of our bank of 2x72” grinders. You will, under the watchful eye of Toby, progress up through the abrasive grits till you archive a super sexy shiny finish.

5 - CHOOSING A HANDLE

We have an extensive selection of premade very classy wa ( Japanese style) handles to chose from, to best reflect your style and personality. Once you’ve picked, you will with Toby’s help, attach you handle to your pride and joy to create your very own master piece.

6 - FINISHING & PHOTO SHOOT

Sharpening your knife is the very final touch to make your creation a true danger to all food groups. This will be done by an instructor to ensure perfection.

With a celebration and giant smiles of satisfaction, we’ll get a group photo and some photos of your achievements. We’ll wrap your knife so you can travel with it. This is when we can bid you fair well so you can go and show your friends and family how amazing you really are.

As Seen on ITV1 – Jimmy and Shivi’s Farmhouse Breakfast

In summer 2025, Murrill Forge was proud to feature on ITV1’s Jimmy and Shivi’s Farmhouse Breakfast. The episode saw chef and presenter Shivi Ramoutar step out of the kitchen and into the forge for a taste of traditional blacksmithing and Knifemaking.

Guided through one of our hands-on forging sessions, Shivi took on the heat, the hammer, and the challenge — with plenty of laughs along the way. It was a brilliant day with the ITV crew, showcasing what Murrill Forge is all about: real craft, real fire, and real experiences.

🎥 Watch the behind-the-scenes video here

Available Courses

-

Make a Kitchen knife in a day

£245

-

Camp knife in a day

£220

-

Blacksmith Day Course

£155

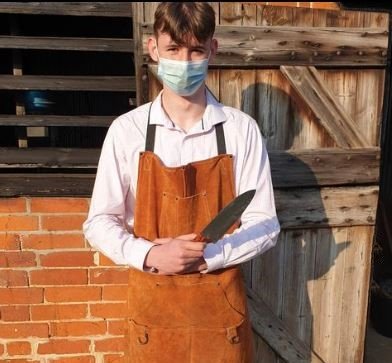

Meet YOUR INSTRUCTOR

Hi, I’m Toby, 21 years married with 4 children, living in the beautiful Suffolk countryside. I was born in Australia but married an English woman, so here I find myself.

I’m an extrovert and love being with people. My passion is seeing adults and children work with their hands, come up with ideas and think outside their normal parameters allowing them to succeed in things they never considered possible.

I learned the skills of blacksmithing and knife making in Australia, and continued to make once here. After requests from customers and friends to show them how I do what I do, I designed a course to give the ultimate experience in making their very own kitchen knife. That one course has now become a series of courses, giving students the ability to come back multiple times and to pick a different course.

Toby

Our Happy customers

Contact us.

If you have questions about an existing booking or about making a booking, drop us a message below and we will get back to you as soon as we can.